PE Protective Film Manufacturer In China

PE protective film, also known as polyethylene protective film, is a surface protection material widely used in industrial manufacturing, architectural decoration, logistics and transportation, and daily life. Made primarily from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), it is manufactured through processes such as blown film and cast film. The film is then coated with an environmentally friendly pressure-sensitive adhesive (or adhesive-free design) and then subjected to a release treatment to create a ready-to-use protective film.

PE Protective Film

Features Of PE Protective Film

PE protective film offers excellent flexibility, tear resistance, and chemical resistance, effectively preventing scratches, abrasions, contamination, corrosion, and other damage to the surface being protected during production, processing, transportation, storage, and installation. Its high transparency ensures that the film remains clear and beautiful for a long time without affecting the appearance of the product.

Material Of PE Protective Film

The primary raw material for PE protective film is polyethylene (PE), one of the most widely used general-purpose plastics. Depending on the performance requirements, low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), or high-density polyethylene (HDPE) is typically used as the base material. LDPE and LLDPE offer excellent flexibility, ductility, and transparency, making them commonly used in protective films requiring high conformability. HDPE, on the other hand, is often used in applications requiring higher mechanical protection due to its high strength and puncture resistance.

Custom Of PE Protective Film

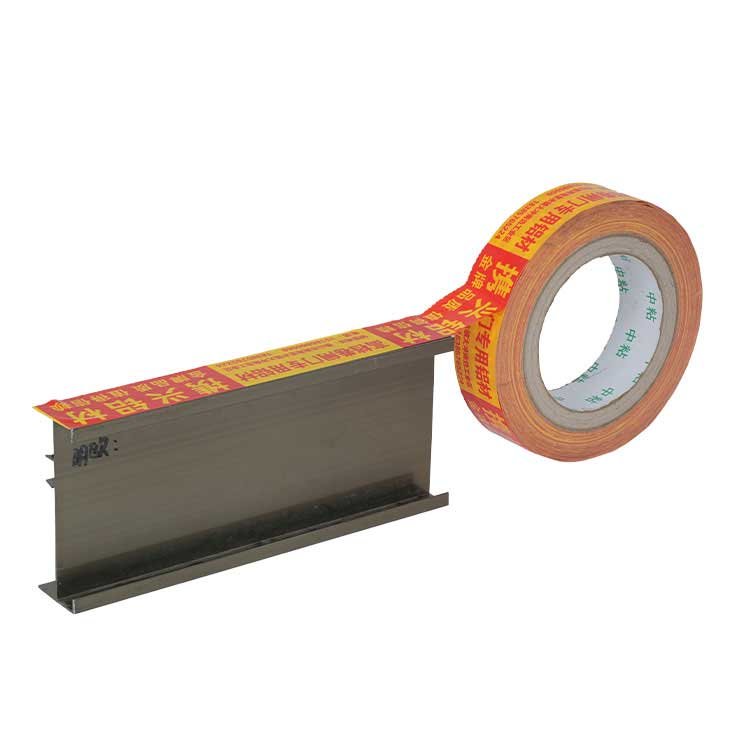

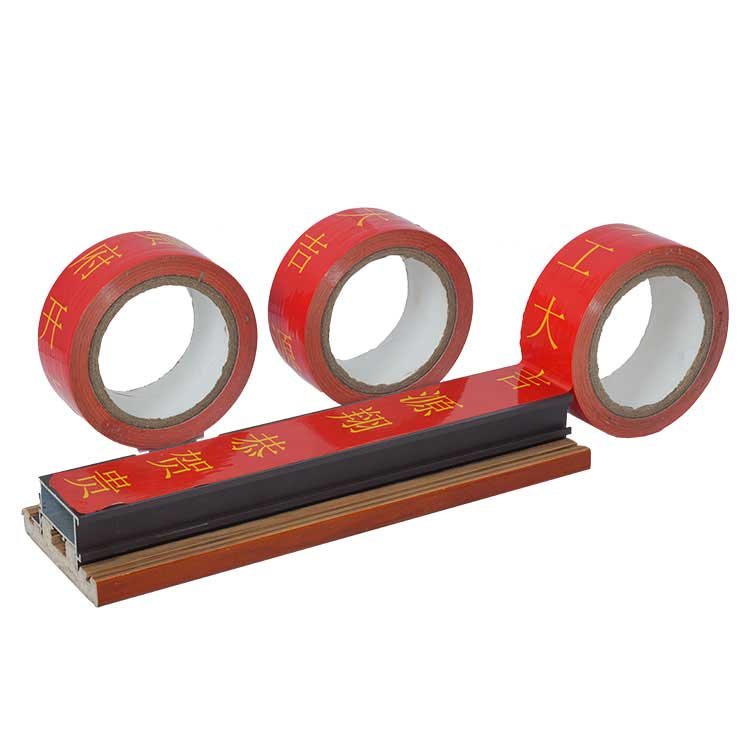

Our PE protective film customization service provides comprehensive, personalized solutions tailored to specific customer needs, and is widely used across various industries and scenarios. Companies can customize PE protective films with varying thicknesses (typically 0.03mm to 0.2mm), widths, lengths, and adhesion levels (low, medium, and high) based on the material, size, processing technology, and usage environment of the product being protected, ensuring a secure fit and no residual adhesive residue when removed. We support customization in a variety of colors, such as transparent, blue, black, and white, for easy identification or to meet specific visual requirements. We can also add special features such as anti-static, UV protection, high-temperature resistance, and anti-fog as needed.

Key Applications of PE Protective Film

PE protective film is commonly used to protect the surface gloss and cleanliness of materials such as curtain wall glass, aluminum-plastic panels, stainless steel sheets, ceramic tiles, and artificial stone. In the home appliance and electronics industries, it is widely applied to the surfaces of products such as refrigerators, washing machines, TV panels, and displays to prevent damage during transportation. In automotive manufacturing, it is used to protect high-value components such as body paint, interior trim, and wheels. PE protective film is also widely used in sheet metal processing, elevator door panels, furniture panels, packaging boxes, and other processes. With its high transparency, excellent flexibility, easy application and removal, and zero adhesive residue, PE protective film not only significantly improves product appearance quality, but also reduces waste and increases customer satisfaction. It is an indispensable protective material in modern industrial production and commodity circulation.

Frequent Asked Questions

Do you accept OEM?

Yes, we do.

How do we know if the quality is good?

First, we use advanced equipment and 100% new raw materials in our co-extrusion casting production method. Second, you can simply test the most important characteristics of stretch film—elongation and puncture resistance—using the test methods described above. Third, we can send you free samples for testing.

Do you offer samples? Are they free or additional?

Yes, we can provide A4 samples for free; you only need to pay for shipping.

What is the delivery time?

It depends on the quantity.

Do you accept small orders?

Yes, we welcome you.

Why Buy From Us

As a leading PE Protective Film manufacturer in China, we offer unmatched quality and reliability. Here are some reasons why you should choose high-quality PVC shrink film:

Olivia

22 years of experience

With over 22 years of experience in the hardware industry, our team provides unparalleled expertise and service.

Exceptional Service

We are committed to providing exceptional customer service and support.

Expertise

Our team is adept at assisting you in selecting designs that perfectly match your specific requirements.

Prompt Shipping

Orders placed before 2 PM are dispatched on the same day to ensure timely delivery.

One-stop PE Protective Film Manufacturing Service

22 years experience. Serving more than 10,000 customers. Professional R&D team. Competitive price.