PVC shrink film is highly flexible, tear-resistant, and has strong tensile strength, making it a suitable alternative to cardboard packaging. Its high shrinkage ratio allows it to tightly wrap items after heat shrinking, making it easy to carry. Its excellent transparency, with a light transmittance of up to 80°, allows for seamless product display and promotion. Its moisture-, water-, and dust-proof properties not only enhance packaging effectiveness but also enhance and protect products.

PVC shrink film is widely used in the outer packaging of doors and windows, building materials, food, medicine, sterilized tableware, stationery, handicrafts, printed materials, hardware and plastic products, electronic appliances, etc. The packaging of irregularly shaped items or commodities can not only meet the functions of moisture-proof, dust-proof, touch-proof, anti-theft, transparent display, etc. of the products, but also increase the aesthetics of the products.

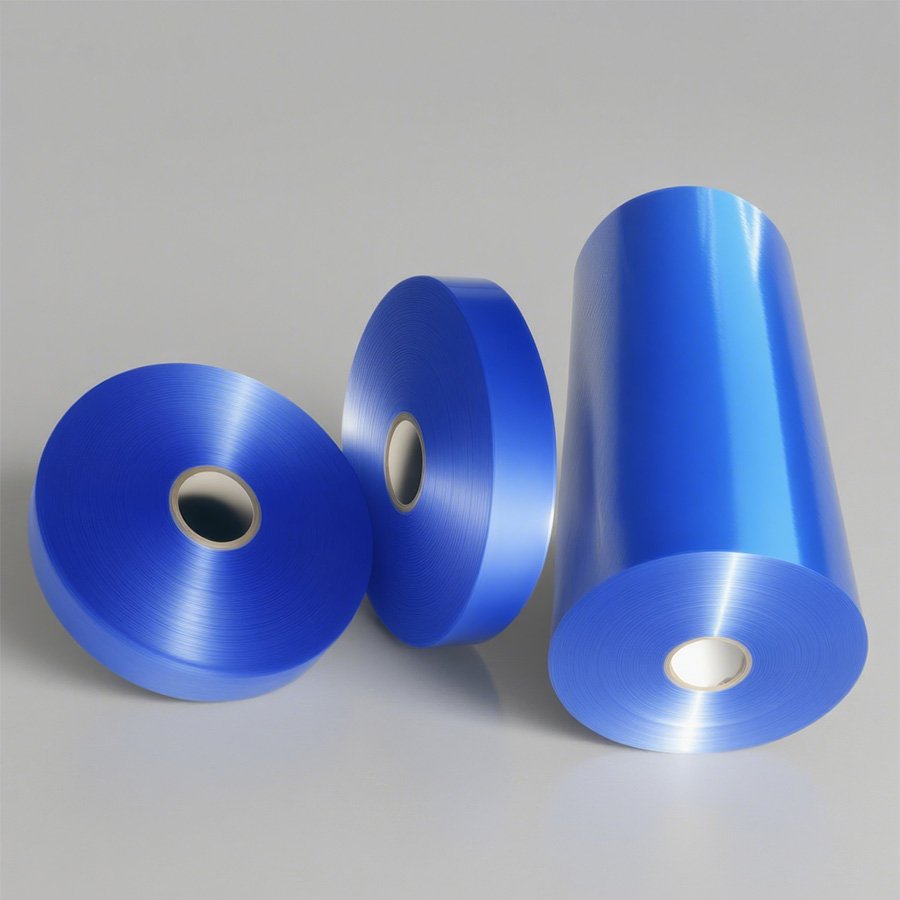

PVC shrink film can also be used to replace various cartons, which not only saves packaging costs but also conforms to the packaging trend. Shrink film (bags) can be processed into flat bags, curved bags, trapezoidal bags, three-dimensional bags and other special-shaped bags.

The diverse range of PVC shrink film is not only suitable for packaging a variety of products and palletizing, facilitating both transportation and sales. It is easily mechanized, saving labor and resources, and can partially replace cardboard and wooden box packaging. Heat shrink film is used to package bottled beer, replacing strapping ropes to prevent explosions and injuries. It has been widely used in doors and windows, building materials, ceramics, tea sets, and mechanical parts. The use of heat shrink film and vapor phase rust inhibition technology in military machinery and hardware tools, replacing anti-rust oil, is of great significance in improving rust prevention capabilities.